Customer Hotline:

Customer Hotline:+1 6193853151

Customer Hotline:

Customer Hotline:+1 6193853151

Product Model:BioHub® SC Sterile Cutter

Product Model:BioHub® SC Sterile Cutter  Manufacturer nature:Manufacturer

Manufacturer nature:Manufacturer  Update time:2025-10-03

Update time:2025-10-03  Visits:104

Visits:104 Product catalog

Related articles

Detailed Introduction

Please be advised that this product is only available for sale and after-sales support in certain regions. For further details, kindly consult with your local sales representative. Thank you for your understanding.

*Sterile disconnection of sampling tubings.

*Sterile disconnection of feeding tubings.

*Sterile transfer of other liquids such as intermediates and primary liquid.

*Secure a Sterile Fluid Path

In a non sterile environment, apply a simple "Press-Cut" act to the metal ring and the single-use tubing to complete sealing and disconnection respectively for the fluid tubing, so as to realize sterile disconnector of the tubing.

*Lightweight, Portable, Easy and Efficient

The product is small and light, independent of utilities, easily movable to wherever you need it, disconnection time as short as 5 seconds, all of which enhances productivity.

*Wide Application Coverage and Powerful Flexibility

There is no tubing material limit. Applicable for either TPE tubing or silica gel tubing. Suitable for the sterile disconnection of tubings with diameter OD1/4" -OD3/4", also, for whether an empty tubing, liquid-contained tubing or pressurized tubing.

*Meticulous Workmanship and After-sales Guarantee

Even coating, smooth surface, mechanical design, low fault rate, and when the cutter jaw reaches the upper limit times, its returnable maintenance is available.

*Rigorous Quality Control and Validation

Rigorous validation has been conduct on the single-use metal disconnection system components to ensure the continuous stability of a sterile disconnection and avoid unnecessary losses caused by cross contamination of customer products.

During production, sterile disconnection of a metal ring by a single person is an easy-to-realize operation.

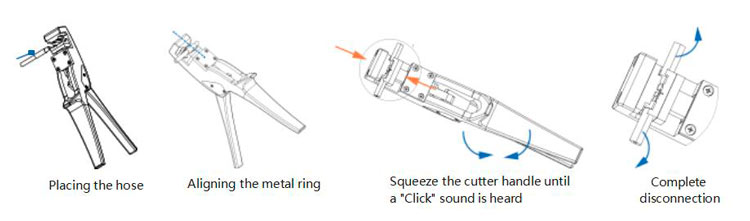

*Use the BioHub® SC Sterile Cutter to place the metal ring to be disconnected at the center from top to bottom of the cutting port.

*Press hard tactfully and then disconnect the tubing.

*The cutting site is securely sealed to form two independent sterile tubings.

| Parameters | Description | |||||

| Material |

Aluminum alloy is adopted for overall design, and the cutting jaw is made by the ZrN-coated steel produced from the chromium molybdenum vanadium gold powder metallurgy |

|||||

| Applicable tubing diameters | ID1/8" —OD1/4" | |||||

| Weight | 580 g | |||||

| Parameters | Description | |||||

| Material |

Aluminum alloy is adopted for overall design, and the cutting jaw is made by the ZrN-coated steel produced from the chromium molybdenum vanadium gold powder metallurgy |

|||||

| Applicable tubing diameters |

Cutting jaw for small diameter tubing Cutting jaw for large diameter tubing |

1/4" * 7/16" | ||||

| 3/8" * 5/8" , 1/2" * 3/4" | ||||||

| Voltage | 12 V (storage battery) | |||||

| IP grade | IP43 | |||||

| Weight | 3kg | |||||

| Item | Product code | |||||

| Manual Sterile Cutter | BLKHCUT01 | |||||

| Electric Sterile Cutter | BLKECUT02 | |||||